Are you tired of breathing in deadly silica dust day after day? Keep your employees and your clients safe from dangerous silica dust with the DUST KILLER silica dust vacuum system.

Why Silica Dust Control?

Employee Health

Every time the silica dust is in the air, you know it is not safe for your employees. You do not want to lose them because of breathing in harmful dust.

Client Satisfaction

A jobsite with dust not only hits your lungs, it settles all over the client’s property leaving memories of dust and dirt associated with your work.

Peace of Mind

You know it could happen. An OSHA fine would be disastrous for your company. Avoid that with a silica dust vacuum system.

Silica Dust Vacuum Systems

Compare Both Models:

| Dust Killer I | Dust Killer II | |

|---|---|---|

| Frame | rugged, galvanized | rugged, galvanized |

| Tires | pneumatic, easy to move | pneumatic, easy to move |

| Inlets | 4”, 6” and 8” | 6” and 8” |

| Dimension | 62” L x 33” W x 74” H | 42” L x 33” W x 74” H |

| Weight | 325 lb | 250 lb |

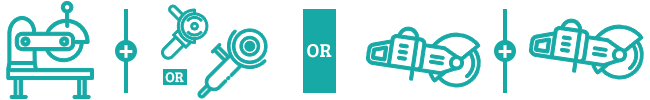

| Capacity | 1900+ cfm Simultaneously supports a 20” table saw, 14” cutoff saw, and 4”-7” grinder OR (3) 14" cutoff saws | 1300+ cfm Simultaneously supports a 20” table saw and 4”-7” grinder OR (2) 14” cutoff saws |

You Have a Choice

Continue down the dusty, well-traveled road, or make a cleaner, safer and healthier choice. Silica dust control is the future, and you can enjoy a dust free jobsite NOW. Your employees will be happier. Your client’s property will be cleaner. And your mind will be at ease.

We Needed a Solution to Protect Our Team

Living

Jobsites with dust flying used to be the norm. We lived in it, breathed it in and felt its harmful impact. It was out of that experience that Jeremy began exploring options for a silica dust control system. But there were only two options at the time:

- huge dust control systems that cost an arm and a leg (and required an extra truck to get it to the jobsite)

- small silica dust vacuums that did not do a sufficient job of capturing dust.

Learning

As we explored the OSHA laws around silica dust, it became clear that few people understood what was required. Jeremy spent hours trying to understand the silica dust control laws surrounding the hardscaping industry. Through this, Jeremy (a certified hardscape instructor) began offering classes with continuing education credits to help contractors understand what it takes to become compliant with OSHA silica dust laws.

Building

With the knowledge Jeremy acquired, he set out to build his own silica dust vacuum system to meet the needs of his own hardscaping crew. Jeremy wanted to protect his employees, his clients and his own pocketbook (from OSHA fines). The result was the DUST KILLER collection including a vacuum system and saw attachments.